表面處理

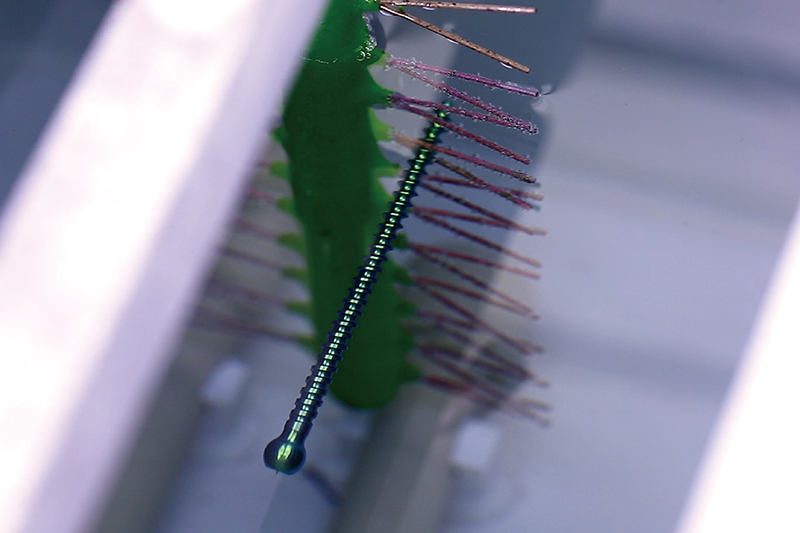

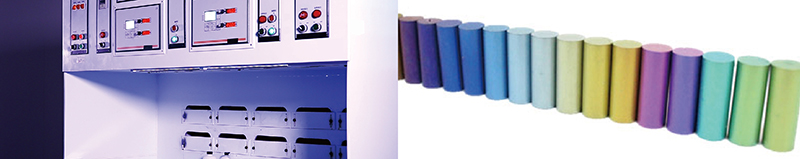

鈦陽極發射處理

鈦發色陽極原理是將被處理之純鈦或鈦合金工件放置於電解液中,施以一定的電壓。鈦合金表面會被電解氧化後生成鈦氧化膜,藉由控制電壓來調整氧化膜厚度,光線經不同膜厚之氧化鈦膜反射、折射,吸收可見光波長(400~700µm)反射出不同互補色而改變鈦合金表面的顏色。實際上鈦合金發色製程中產生之鈦氧化膜本身並無顏色。此氧化膜非電鍍上之表面,為將原本基材氧化而成,故不會有剝落問題產生。

技術應用

鈦發色處理技術,耐蝕性極佳、鍍膜穩定高,用於醫療禃入手術時,不易析出離子、無毒性應用於醫療業,醫療器材如:人工關節、齒根、心臟瓣膜、人工骨骼等…。 鈦發色讓工件產生多種顏色,可增加辨視效果,因物件尺寸、種類劃分應用於醫療業,如骨鈑及骨釘、齒根、人工關節,或工業,如螺絲、螺絲帽等。

其他技術

雷射雕刻

汽化效應在雷射對材料的作用過程中,被雕刻材料的表面溫度急劇上升,又會加速材料對雷射能量的吸收,當達到材料的汽化溫度時...

酸蝕處理

透過化學浸蝕,清除其表面粘附的油脂、自然氧化膜和灰塵等污染物,使金屬基體裸露出來,形成均勻的活化表面,並產生微細孔洞...